The rise of flexible printed electronics could be attributed to the way it is churning out innovative applications that can optimise costs and boost productivity in sectors like automotives, consumer electronics, consumer durables and healthcare. The shift is being fuelled by the use of new flexible materials, new methods of manufacturing and the need for design freedom. Printed electronics is essentially the confluence of high-end printing and flexible electronics

Mumbai-based Classic Stripes is among the few companies in the country that were able to tap into the opportunity presented by flexible printed electronics early on to scale ahead. The firm is helping industries like electronics and automotive to enhance the consumer appeal of their product applications.

What sets its products apart is the integration of visual decoration, illumination and sensing to create products which are thin and flexible and can be integrated into consumer products in different industries.

From safety sensors to powering touch-controlled user interfaces in appliances like coffee machines, washing machines, refrigerators, light switches and car interiors, Classic Stripes is pioneering exciting aesthetics and electronics in their applications, thanks to the power of technologies like printed electronics.

The technologies that have had the pride of place in Classic Stripes’ product range are the Flexible Force Sensing Resistor (FlexFSR) and Flexible Electro Luminescence (EL), which form the base of some of the most innovative solutions designed by the company. They’re thin, flexible, reliable and can be configured in various ways. They offer design freedom to product designers and can be leveraged according to their specific needs.

Moreover, these technologies ensure a stable performance even at high temperatures and can be integrated in household applications like cordless keyboards, touch pads, remote controls and mobile computing applications. They can even deliver results in moist and humid conditions.

Here are a few Classic Stripes products that are manufactured by integrating the Flexible FSR technology and the EL technology:

Large/small size force sensors: The product consists of sensing materials printed on flexible substrates that provide output when activated by applying force on the active area.

Ring potentiometer: It’s an FSR-based position sensor, which has a circular sensing area and a set of LEDs placed circularly. The LEDs will light up as one applies force on the sensing dial.

Integrated linear potentiometer and FSR: This device senses both force and position. The LEDs are placed linearly and can be activated by moving one's finger along the sensing area.

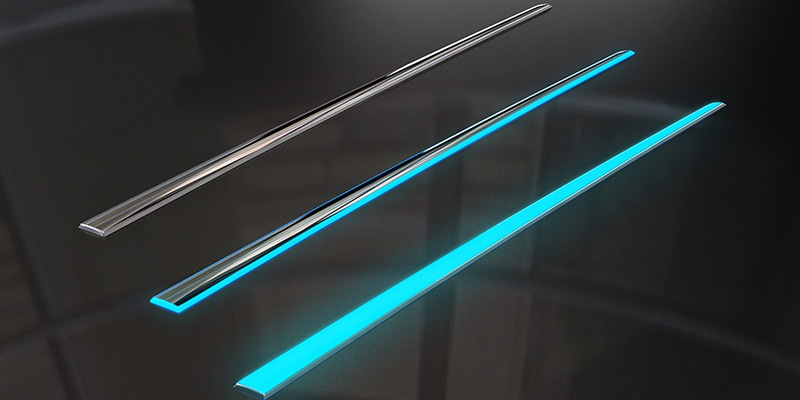

Illuminated decals, 3D badging, printed heaters: Classic Stripes has been leveraging its cutting-edge technology and screen-printing prowess to build solutions that offer product designers a lot of flexibility and unique curved form factors. These solutions are designed to be thin in width and flexible, and can be customised according to the specifications of any industry such as automotive, consumer durables and appliances, medical devices and advertising.

Classic Stripes’s Flexible Electro Luminescence technology is not only light in weight, but also consumes less power than traditional electroluminescence technologies, all the while being as well as bringing high value. The key market segments where this technology can be leveraged include automotive, consumer electronics, white goods, fitness gear, medical equipment/devices and advertising IoT.

Explaining the USP of these products, Classic Stripes, Managing Director, Salil Musale, said, “For brands and designers to keep innovating and developing next-generation exciting consumer products, they need products like ours that will enable them to create differentiated products that their customers find exciting to use and interact with.”

Link : https://yourstory.com/2021/05/classic-stripes-leveraging-new-age-electronics-building-innovative-solutions

Author :- Team YS ( )

May 31, 2021 at 10:39AM

YourStory