CII’s annual knowledge summit was held entirely online this month, titled CII Global Knowledge Virtual Summit 2020: Knowledge in the Age of Artificial Intelligence. It was also supported by the Knowledge Management Global Network (KMGN).

YourStory was the media partner for the flagship summits in 2019 and 2020. See our 15-part article series, which includes Knowledge Leadership, KM in the Age of AI, Gamification, Storytelling, Knowledge Sharing in the COVID-19 Era, and Eye on AI.

YourStory also moderated the panel on Knowledge Excellence: Winners of the Global MIKE Awards. (See my book series The KM Chronicles for case studies of earlier winners of the MAKE Awards and Singapore KM Excellence Awards.)

Mobarakeh Steel Company (MSC) in Iran is a winner of the Global MIKE award. MSC is regarded as the largest steel maker of the MENA (Middle East and Northern Africa) region, and one of the largest industrial complexes operating in Iran. It also owns the football club Sepahan, based in Isfahan.

Akbar Golbou is a member of the team leading knowledge management (KM) at MSC. He has a background in computer software engineering, business and finance, and is the IT manager at MSC.

Akbar joins YourStory in this in-depth conversation on MSC’s knowledge journey, business impacts, and next steps. See also our earlier profiles of MIKE award winners Tata Steel, Cognizant Technology Solutions, Afcons Infrastructure, and Petroleum Development Oman.

Edited excerpts of the interview below.

YourStory [YS]: How would you describe your KM journey from your early years to today?

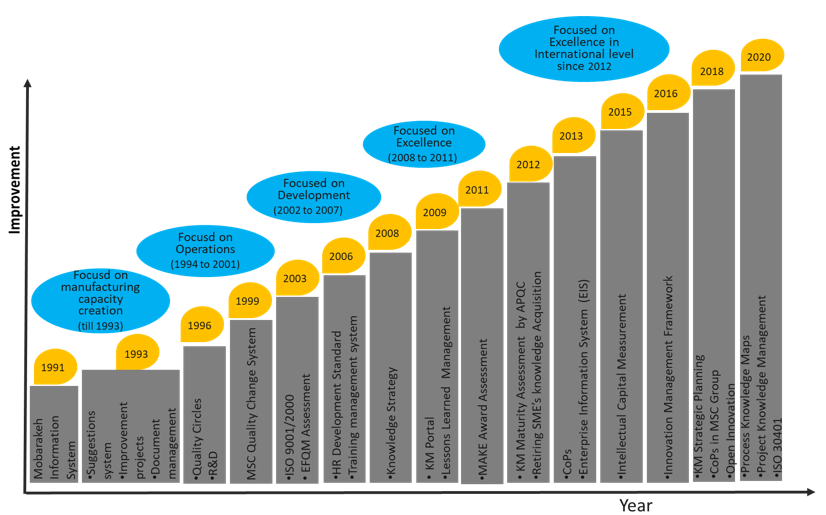

Akbar Golbou [AG]: Since the launch of the company in 1991, various KM approaches and tools have been developed in different time periods of MSC’s history-based, on strategic business direction.

From 1991 till 1993, MSC was focused on creating manufacturing capacity, so Mobarakeh Information System (MIS) was developed as the very first KM tool to transfer information from design processes to production lines. Document Management System, Suggestions System (SS), and Improvement Teams and Projects were also developed in this period to ensure the existence of high-quality production capacity.

From 1994 to 2001, MSC’s focus moved to operating the created capacity. Quality Circles, R&D and Quality Change System were developed to improve the performance of the business processes.

The period from 2002 to 2007 was the time for business development. Hence, ISO 9001/2000 and People Development Standard (PDS) audits, along with Organisational Excellence and Productivity Award assessment, were performed to find KM improvement opportunities in MSC. Training Management System was implemented in this period, as well as to increase efficiency and affectivity of individual learning approaches.

From 2008 to 2011, MSC’s focus moved on to excellence. To support the change, we started formulating our knowledge strategies in the business strategic planning process. MSC’s Knowledge Portal, as well as a Lessons Learned approach, were developed in this period. We also participated in MAKE (Most Admired Knowledge Enterprise) award for the first time to determine our KM programme excellence level and opportunities.

Since 2012, MSC has focused on excellence at the international level. To move in this direction, we started benchmarking our KM programme annually against international best practices using MAKE assessment and APQC’s KM Capability Assessment Tool (CAT) reports. Based on the findings and our business needs, we developed communities of practice (CoPs), critical knowledge capture, innovation management framework, and intellectual capital (IC) measurement.

In 2018 we recognised a need for KM Strategic Planning to be able to take the most effective KM actions, see all KM activities across the company as one picture, integrate them, and ensure the existence of the required enablers for each.

Our KM strategic planning revealed the need for process-based knowledge maps, CoPs across the MSC Group, open innovation, and project KM, which are currently being developed in MSC. We were certified for ISO 30401 in 2020.

YS: What are some impacts you can share of how KM has benefited your organisation?

AG: We have benefited from practising KM in many ways. Here are some examples of KM impact on our processes.

- Increased income from producing special grades of products

- Reduced water consumption

- Reduced energy consumption

- Increased market value of HOSCO (one of MSC’s subsidiaries) after acquisition by MSC and knowledge transfer to the company

- Production increase in SABA Steel plant (an MSC subsidiary) to its nominal capacity after the acquisition and commissioning by MSC.

- Economic savings through manufacturing our strategic supply needs in Iran instead of importing them from foreign resources. To achieve this, we have numerous knowledge-sharing meetings with our Iranian suppliers and vendors to help them in the manufacturing process.

- 5,202 billion IRR (Iranian real) saving from implementing 63 improvement projects.

KM journey and impacts at MSC

YS: Can you give some examples of processes where knowledge is embedded in the workflow, and other processes that require extra activity to manage or create knowledge?

AG: MSC’s Process Management System (BPM) and Enterprise Management System (EIS) together manage and embed knowledge and information in all business processes.

Knowledge and Information inputs and outputs of a process are determined in the BPM and are provided for users through MSC’s EIS.

YS: What are some communities of practice (CoPs) you have that involve knowledge inputs from external members?

AG: We have CoPs such as ‘Direct Reduction’ that have members from other MSC Group companies. Practitioners from subsidiary companies like HOSCO, Sefid Dasht and SABA give inputs to these CoPs.

We benefit from crowdsourcing in our open innovation approach. MSC has established an innovation and creativity centre in collaboration with Tehran University. MSC’s problems are addressed in this centre and experts from various disciplines and institutes are invited to work on them.

YS: Tell us about your KM team – what are the roles and responsibilities?

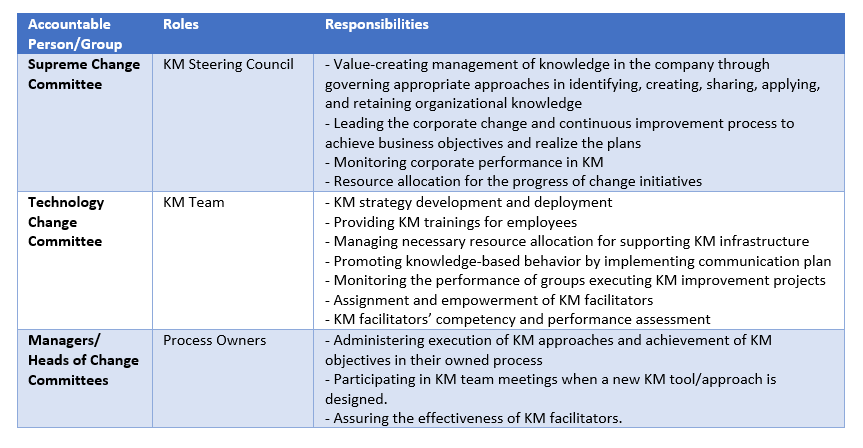

AG: Policies and strategies for all activities pertaining to management and change systems (including KM) are made via change committees at three levels: Supreme Change Committee (headed by the CEO), 19 main committees, and departmental change committees (a total of 125 committees).

This structure is tasked with leading and managing all activities of the KM, making revisions and improving KM activities as necessary. The following table shows different groups in charge of KM.

KM roles and responsibilities at MSC

YS: How are you structuring separate activities for incremental and radical innovation?

AG: Incremental and radical innovation are managed in two different processes in MSC. A big leap or radical innovation is managed in the R&D department and the Excellence Department is responsible for incremental improvements.

YS: What are some ways in which you are leveraging AI along with KM?

AG: Because of MSC’s focus on digital transformation, it has recently established a new organisational department (Smart Systems and Digitalisation Department) to develop AI in the company. The department has created a roadmap to digitalisation and Reference Architectural Model Industrie 4.0 (RAMI 4.0) has been chosen as the reference model in this regard.

The required infrastructure for digitalisation system has been prepared, and AI is being leveraged in some business processes such as marketing and procurement. We hope we can benefit from AI in KM in the near future as well.

YS: What are some emerging trends which will affect the future of your KM strategy?

AG: We believe Industry 4.0 and Artificial Intelligence will mainly affect our KM strategy. We should soon employ data and text mining technologies to better extract and classify knowledge.

YS: How has the COVID-19 crisis impacted knowledge sharing priorities in your company? What has changed and what remains the same?

AG: MSC has developed its KM strategic framework and revises it continuously in case of impacting changes in the internal and external environment.

Here are some of our KM priorities during the COVID-19 crisis.

- Forming a knowledge transfer group to share COVID-19 period experiences

- Supporting distance working teams and employees for online meetings

- Facilitating external access (for distance working employees) to the organisational resources (e.g. procedures, workflows)

- Creating online forums to answer employee questions across the company and MSC Group

- Networking and developing online CoPs to facilitate knowledge sharing across the company and MSC Group

- Supporting senior leaders to get adopted to the new situation (e.g. digital transformation and online participatory tools) across the company and MSC Group

- Collection, process, classification and sharing MSC’s COVID-19 prevention experiences across the company and MSC Group.

Our KM approaches (such as LL, SS, improvement teams and projects, R&D) have been kept active during COVID-19 crisis, though have become limited and are performed mainly online.

Akbar Golbou, MSC

YS: What are the next steps in your KM journey?

AG:

- Developing process knowledge maps and the required IT system: Although we do annual strategic knowledge mapping (in the business strategic planning process), we have identified a need to process knowledge maps to identify critical knowledge and knowledge gaps more in detail.

- CoPs across MSC group: MSC is going to develop CoPs among MSC group companies to increase knowledge sharing between MSC and its subsidiaries and enhance their performance.

- Developing our knowledge portal based on the increased needs in the MSC group.

YS: Based on your experience, what are your top three tips to business leaders on how they should harness KM?

AG:

- Find the need

It is super important to identify business needs for KM be able to find the advocates you need for KM implementation. It guarantees KM effectiveness and stakeholder satisfaction that KM strives to achieve.

- Develop your KM implementation strategy and framework

You should have a formal document indicating how you are going to address the business need for KM. What are the KM objectives and desired effects in your organisation? What are the KM approaches and tools that can realise your objectives? What enabler should be developed to support the approaches?

- Find and communicate KM success stories

It is so important to show tangible effects of KM to the organisation to gather their support for KM. Look for the situations in which KM approaches have been able to make a noticeable improvement, and let others know about it.

(Edited by Saheli Sen Gupta)

Want to make your startup journey smooth? YS Education brings a comprehensive Funding Course, where you also get a chance to pitch your business plan to top investors. Click here to know more.

Link : https://yourstory.com/2020/07/cii-knowledge-management-mobarakeh-steel

Author :- Madanmohan Rao ( )

July 24, 2020 at 07:15AM

YourStory