The effects of climate change have begun to show up across the world in various forms of destruction – wildfires due to excessive heat, cyclones, heat waves, and unseasonal rains that ruin crops, to name a few.

Organisations have been taking steps to mitigate some of the damage human activity has caused on the environment, but the effort requires much wider participation.

Waste and refuse is one of the biggest sources of water and land pollution. Wanton waste creation, which is then improperly disposed of, is an unmanageable menace that keeps pressuring the planet’s life-sustaining resources.

Among the many organisations and companies trying to solve the waste management problem is Ahmedabad-based Ishitva Robotic Systems.

Jitesh Dadlani and Sandip Singh, co-founders, Ishitva Robotic Systems

Founded in 2018 by Jitesh Dadlani and Sandip Singh, Ishitva uses deep-tech such as artificial intelligence (AI), machine learning (ML), and IoT to effectively manage waste, and convert reusable products into something useful.

In an interview with YourStory, the founders said that the startup's proprietary device’s automatic sorting system helps improve both quantity, as well as the quality of recycling activities. This, in turn, reduces dumping and burning of dry waste such as scraps, polythene bags, plastic bottles, etc.

“Our solutions use computer vision to make sorting more efficient at different stages of the waste value chain. With our proprietary algorithm ‘ishitvAI’, we have been able to achieve automated, high volume, and better quality sorting in a fraction of time, as compared to human sorting,” says Jitesh.

Using technology for sorting wastes

According to the company, waste sorting in India is currently mostly done by humans. The process is not only unhygienic and tedious, but also dangerous for human beings.

Apart from this, human sorting is a slow, inaccurate process. These factors increase the chances of more waste being dumped, and the possibility of some waste not making its way into the recycling ecosystem.

Sandip explained that the focus on sorting is important because the absence of proper sorting makes the whole process of creating reusable products out of waste, redundant, and destroys the circular value chain.

For the uninitiated, the circular value or supply chain encourages manufacturers and producers to collect waste, recycle whatever they can to develop new products, and then resell those items to the market.

The idea to use tech to sort dry waste occurred to Jitesh who – once he came back from Dubai where he was working as a software engineer – saw that waste sorting was a big problem in India, and people – including children – used to hand-sort dry waste.

“I noticed that automobile and ecommerce players were using robots to sort packages, and I thought why can’t we use the same mechanism for sorting wastes.”

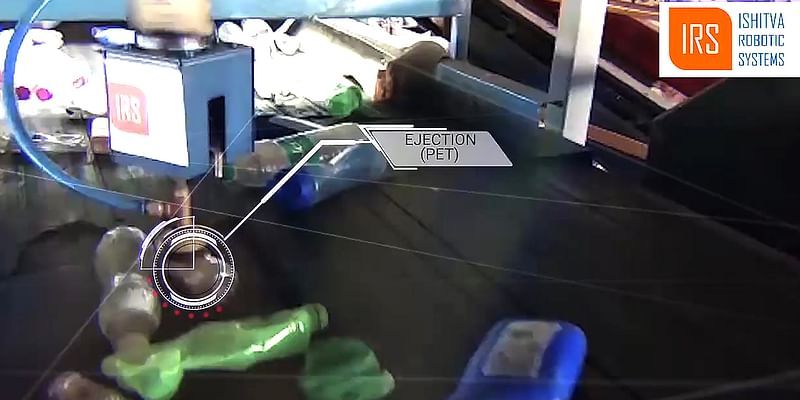

Ishitva’s machine uses AI, robotics, and ML to analyse the chemical composition of waste, and sort them into recyclable and non-recyclable categories.

YUTA system. Credit: Ishitva Robotic System

Products

Ishitva currently offers a range of solutions including SUKA (AI-powered air sorting), YUTA, (AI-powered robotic sorting), Netra AI Vision system, which helps identify waste, and smart bins.

The AI-powered Netra identifies the waste, learns about its contents by capturing images, and then scans for recyclable material.

“The platform is designed to detect more than two million images. Using technology, the platform classifies the recyclables faster, and sends precise instructions to the air sorter system.”

SUKA uses the Netra’s vision system to identify and sort waste, while YUTA identifies the complex composition of waste, and picks up recyclables from the conveyor belt.

Using smart bins, Ishitva has been able to collect data on the kind of waste being generated in different areas, which the company says will be useful for it to understand and identify any waste disposal trends that could result in better management.

SUKA system. Credit: Ishitva Robotic Systems

Growth and revenue model

The company positions itself as an equipment provider that builds solutions for companies with materials recovery facility (MRF).

Material recovery facility is a special plant that collects solid-waste, recycles them, and then sells them back to manufacturers as raw materials for new products.

Sandip says the startup's solution can be both retrofitted into existing MRF plants, and also installed in new ones. While the founders declined to share pricing and revenue details, they said the price depended on the client’s requirements.

The startup has already installed its machine at a plant in Ahmedabad, and is on track to fulfil orders from Maharashtra and Gujarat.

Currently, Ishitva has been seeing an increase in order volumes, thanks to the coronavirus pandemic, which forced waste and sanitation workers to go back to their hometowns.

Looking ahead, the founders say they are looking to raise Series A funding in order to scale up and capture more of the Indian market. Last year, the company had raised seed funding from angel investor Sandeep Patel.

(Edited by Aparajita Saxena)

Want to make your startup journey smooth? YS Education brings a comprehensive Funding and Startup Course. Learn from India's top investors and entrepreneurs. Click here to know more.

Link : https://yourstory.com/2020/05/ahmedabad-startup-ishitva-robotic-systems-recycle-waste

Author :- Shreya Ganguly ( )

May 26, 2020 at 05:40AM

YourStory